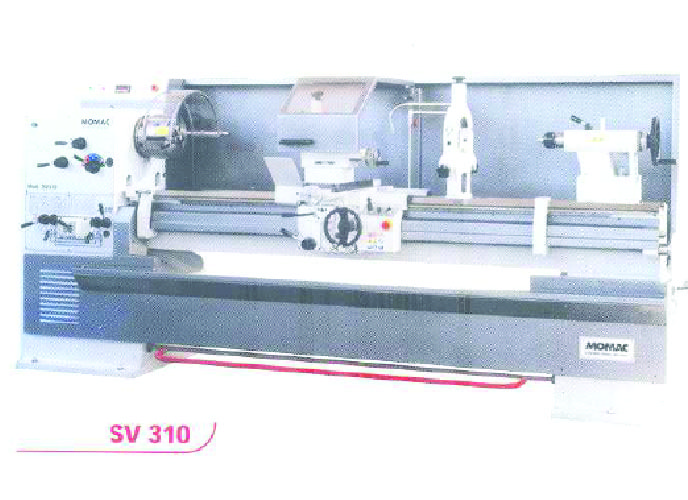

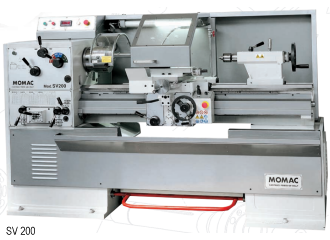

Description

CONSTRUCTION FEATURES

The apron is made of cast iron and is completely closed. It contains, in an oil bath, the kinematics for the feeds and threads. A mechanical safety device with which the apron is equipped prevents the automatic feed and threading mechanisms from being activated simultaneously.

The Norton box is of the complete centralized control type and allows the execution of a high number of feed steps and threads without the need to change gears on the head straddling the transmission.

The head consists of a well-sized monobloc cast in stabilized GG 25 cast iron. It has been carefully studied and strongly ribbed in order to obtain the massism rigidity and a complete absence of vibrations even in very demanding working conditions.

All the gears and pinions of the head, the norton box and the apron are tempered and ground to allow high resistance and high silence. The pinions are mounted on roller bearings. The different mechanisms are lubricated in an oil bath.

The horizontal type bench is made entirely of special cast iron suitable for induction hardening: a rational arrangement of ribs and a sturdy anchorage to the base ensure perfect rigidity to the complex and excellent absorption of vibrations.

The guides are prismatic integral type induction hardened and ground (hardness 400-460 HB)

The main spindle is balanced, well dimensioned and mounted on tapered roller bearings of great precision and load capacity. It is also equipped with a rear game registration dial.

The carriages are amply sized and equipped with a centralized manual guide lubrication system. The transversal carriage and the upper trolley are equipped with a conical steel gib for the recovery of the games.

The transverse screw, hardened and ground, is mounted on roller bearings and guarantees high durability and great reliability.

The tailstock is of very robust construction. iThe sleeve is tempered and ground and has an extraction slot. The screw is mounted on bearings with high load capacity.

The modern and refined design is the ideal combination of safety and comfort.

Special protections make the machine safe and at the same time ergonomic and easy to maneuver.

Machines compliant with EC Machinery Directive 2006/42 EEC.